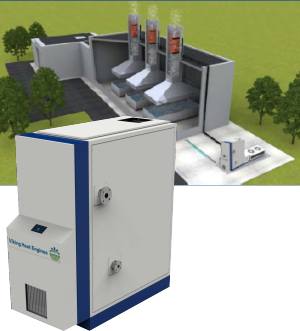

CraftEngine: Innovative technology to use residual heat

ProSign GmbH is developing and supplying the complete automation platform for the CraftEngine project of the companies Heat Engines AS and AVL Schrick. ProSign’s scope of service involves:

- adaption and supply of the programming system iCon-L 6

- development and supply of an innovative application-specific multi-processor control system with touch display (Qseven + Cortex M3)

- adaption and supply of the Linux RT image for the Qseven platform

- adaption and supply of the RTOS implementation for the Cortex M3

- adaption and supply of PAC kernels (iCon-L runtime kernels) for both processor platforms

- development of a service-oriented inter-processor communication betwen Qseven and Cortex M3

- delivery of the remote maintenance solution over VNC

- Designing and consulting during application development

- Development of the software context diagram and the process context diagram

- Designing the HMI (page flow diagram and design)

- Integration of a MATLAB control model

Information about CraftEngine...

CraftEngine project

| Project | CraftEngine |

|---|---|

| Short description | Development and production of a serial machine to produce electric energy from residual heat |

| Customer | AVL-Schrick, Viking Development Group |

| Service provided by ProSign | - adaption and supply of the programming system iCon-L 6 - development and supply of an innovative application-specific multi-processor control system with touch display (Qseven + Cortex M3) - adaption and supply of the Linux RT image for the Qseven platform - adaption and supply of the RTOS implementation for the Cortex M3 - adaption and supply of PAC kernels (iCon-L runtime kernels) for both processor platforms - development of a service-oriented inter-processor communication betwen Qseven and Cortex M3 - delivery of the remote maintenance solution over VNC - Designing and consulting during application development -> Development of the software context diagram and the process context diagram -> Designing the HMI (page flow diagram and design) -> Integration of a MATLAB control model |

| iCon-L version | 6.0 |

| Target systems | - 2 independent controls - Qseven + Cortex M3 |

| Process data points | - 60 I/O data points directly and over the CAN bus |

| Features | - MATLAB models integrated - >2000 Adjustment parameters (family of characteristics) |

| Size of the application | - Qseven control ?? FBs - Cortex M3 control ?? FBs - Visualizing and parameter blocks have not been counted |